Laser Cutting/Punching

Fiber Optic Laser Cutting and High-Speed Punching

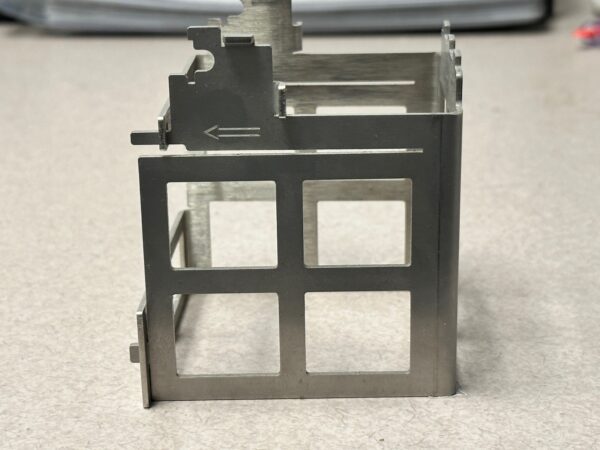

With our Amada LC 2515 C1 AJ, Fiber optic laser/high-speed turret punch with a 3KW laser, and a 22-Ton 44 tool station turret punch, we can process features such as louvers, lances, up forming, and tapping of holes. The ASR 3015N TK multi-tier material stacking tower allows us to run various materials/jobs to maximize production and decrease lead times. With features such as self-loading and unloading, parts picking and sorting, we can run lights out 24/7 manufacturing. The sheet handling capacity of up to 60” wide x 120” in length. Laser cutting/punching materials with a thickness from .015” to .180” thick allow us to cover all your sheet metal needs.

Our Amada ENSIS 3015 AJ 3kw fiber optic laser allows us to cut material as thin as .015” up to .625” thick steel plates and .375” stainless steel and aluminum plates with precision. With features such as self-loading and unloading, we can run lights out 24/7 manufacturing. Sheet handling capacity of up to 60” wide x 120” length, allows us to cover all your sheet metal needs.

Our Amada EMK 3612, 33-ton 58 tool station allows us to form features such as louvers, lances, and other shapes that otherwise cannot be laser cut. With features such as self-loading and unloading, we can run lights out 24/7 manufacturing. Sheet handling capacity of up to 60” wide x 120” length. Punching of materials with a thickness from .048” up to .125” thick allows us to cover all your sheet metal needs.

Contact Us

We’ll help you answer even the toughest sheet metal questions.